In the world of construction and infrastructure development, ensuring lasting protection against water infiltration stands as one of the most critical challenges. Qingdao Eaststar Plastic Machinery Co., Ltd. proudly introduces its groundbreaking TPE Single-screw Non-woven Composite Co-extrusion Waterstop Production Equipment, engineered to redefine industry standards. This state-of-the-art machinery specializes in manufacturing high-performance waterstop profiles through an innovative co-extrusion process that integrates thermoplastic elastomers (TPE) with non-woven composite materials. The result is a superior sealing solution that offers unparalleled durability, flexibility, and resistance to environmental stressors.

Traditional waterstop production methods often struggle with consistency and material integration, leading to vulnerabilities in critical structures such as basements, tunnels, and water treatment plants. Our equipment eliminates these concerns by leveraging single-screw extrusion technology that ensures precise material control and uniform output. The non-woven composite layer enhances the waterstop's mechanical properties, providing exceptional tear resistance and longevity. Whether for civil engineering projects or industrial applications, this equipment delivers products that meet rigorous international quality standards, giving engineers and contractors the confidence to build structures that stand the test of time.

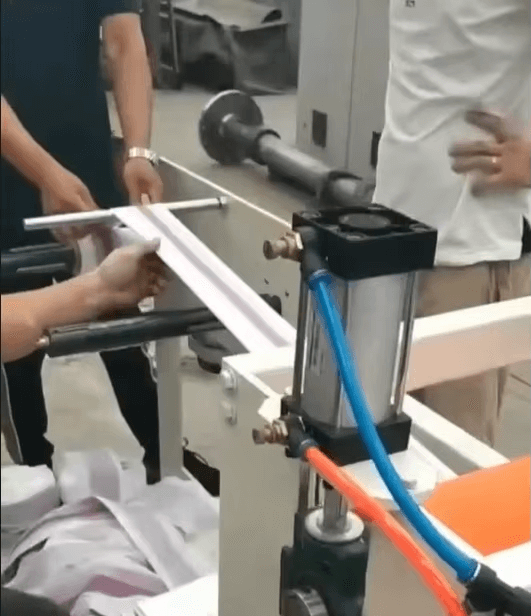

The equipment masterfully combines TPE with non-woven composites, creating waterstop profiles that exhibit both elasticity and structural integrity. This hybrid approach prevents common failures like cracking under movement or degradation from chemical exposure.

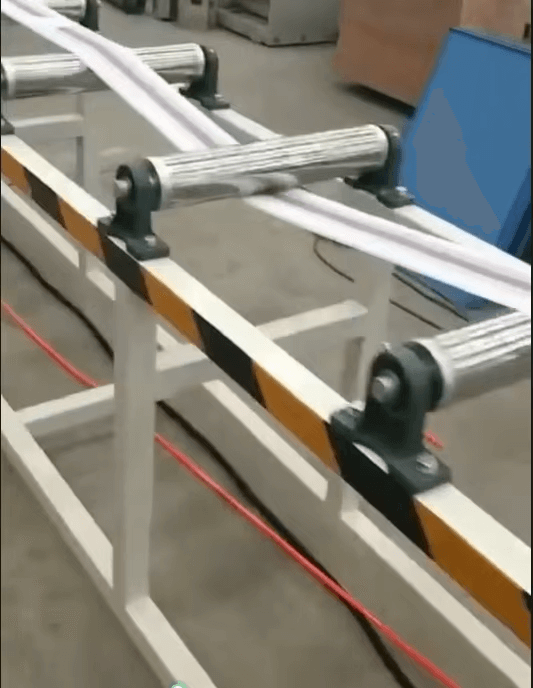

With advanced single-screw extruders, the system maintains exact temperature and pressure controls, ensuring each waterstop produced has consistent dimensions and material properties. This precision translates to reliable performance in diverse environmental conditions.

Designed with sustainability in mind, the machinery optimizes energy consumption without compromising output quality. Reduced operational costs make it an economically smart choice for high-volume production facilities.

Many production units face issues like material waste, inconsistent product quality, and high maintenance downtime. Our equipment directly tackles these problems through intelligent design and robust engineering. For instance, the integrated cooling system ensures rapid setting of composites, reducing cycle times by up to 30%. Additionally, automated monitoring detects potential faults early, minimizing unplanned stoppages.

Below are the detailed technical parameters that highlight the equipment's capabilities:

| Parameter | Specification | Benefit |

|---|---|---|

| Screw Diameter | 45-120 mm | Accommodates various production scales |

| Output Capacity | 150-500 kg/h | High throughput for demanding projects |

| Power Consumption | 25-75 kW | Energy-efficient operation |

| Control System | PLC with touch interface | User-friendly and precise adjustments |

| Max Operating Temperature | 250°C | Handles diverse material grades |

This machinery serves a wide range of professionals and industries focused on creating resilient infrastructure. Construction material manufacturers will find it indispensable for producing reliable waterstop products used in concrete joints, expansion joints, and structural seams. Civil engineering firms and contractors can leverage the equipment to develop custom profiles tailored to specific project requirements, such as subway systems, bridges, and reservoirs.

Additionally, industrial plants involved in water management, including sewage treatment facilities and hydropower stations, benefit from the equipment's ability to produce waterstops that resist aggressive chemicals and constant moisture. By investing in this technology, businesses not only enhance their product offerings but also build a reputation for quality and reliability in competitive markets.

Imagine overseeing a major infrastructure project without worrying about water leakage compromising the structure's integrity. The waterstop profiles manufactured using our equipment provide that assurance, allowing engineers and builders to focus on innovation rather than damage control. Clients report a significant reduction in callbacks and repairs, leading to higher customer satisfaction and strengthened professional relationships.

Beyond practical benefits, users experience a profound sense of pride in delivering structures that safeguard communities and environments. From preventing basement floods in residential complexes to ensuring the durability of public transportation networks, this equipment plays a vital role in creating safer, more sustainable spaces for generations to come.

While several manufacturers offer extrusion equipment, Qingdao Eaststar's TPE Single-screw Non-woven Composite Co-extrusion Waterstop Production Equipment stands out through its holistic approach to durability and efficiency. Unlike conventional systems that may require frequent recalibration, our design incorporates self-adjusting mechanisms that maintain optimal performance over extended periods. The co-extrusion capability allows for the creation of multi-layer profiles with tailored properties—such as a soft TPE core for flexibility and a tough non-woven surface for abrasion resistance—without needing secondary processing.

Moreover, our commitment to continuous improvement means that each unit benefits from the latest advancements in polymer processing. From reduced material waste to enhanced automation features, every aspect is fine-tuned to exceed expectations and adapt to evolving industry needs.

What types of TPE materials are compatible with this equipment?

The equipment is designed to process a wide range of thermoplastic elastomers, including SEBS, SBS, and TPU-based compounds. Its versatile screw and barrel configuration allow for adjustments in temperature and shear rates, accommodating different melt flow indices and hardness levels. This flexibility ensures optimal performance whether producing soft, flexible waterstops or harder, more rigid profiles.

How does the non-woven composite enhance the waterstop's performance?

The non-woven composite layer acts as a reinforcement, significantly improving tensile strength and puncture resistance. When co-extruded with TPE, it creates a synergistic effect where the elasticity of TPE combines with the durability of the composite. This results in waterstops that can withstand structural movements, soil pressures, and long-term environmental exposure without failing.

Can the equipment be customized for specific production needs?

Yes, Qingdao Eaststar Plastic Machinery Co., Ltd. offers customization options to match unique operational requirements. This includes adjustable screw designs, modular die systems for different profile shapes, and integration with auxiliary equipment like haul-offs and cutters. Our engineering team works closely with clients to tailor solutions that optimize productivity and product quality.

What kind of maintenance schedule is recommended for this machinery?

Routine maintenance involves cleaning the screw and barrel after material changes, inspecting heaters and sensors monthly, and lubricating moving parts as per the operator's manual. The equipment is built with easily accessible components to simplify these tasks. With proper care, users can expect years of reliable service with minimal downtime.

Is training provided for operating the equipment?

Absolutely. We provide comprehensive training sessions covering setup, operation, troubleshooting, and safety protocols. These can be conducted on-site or at our facility, ensuring that your team gains the confidence and skills needed to maximize the equipment's potential. Ongoing technical support is also available to address any questions that may arise.

2.4m Manure Removal Belt Extrusion Line

2.4m Manure Removal Belt Extrusion Line TPE/TPO Waterstop Production Line

TPE/TPO Waterstop Production Line TPE-1000mm anti-slip mat equipment car floor mats

TPE-1000mm anti-slip mat equipment car floor mats One-out-two PVC profile production line for livestock breeding

One-out-two PVC profile production line for livestock breeding TPE+non-woven Fabric Composite Co-extrusion-waterstop Production Line

TPE+non-woven Fabric Composite Co-extrusion-waterstop Production Line Pa Sheet Extrusion Line Single Screw Extruder Machine

Pa Sheet Extrusion Line Single Screw Extruder Machine